3.6-Ton Electric Remote Control Hydraulic Excavators

Total weight :3990kg

Bucket capacity:0.13m³

Remote control distance:5km

Power system

All-electric drive: It adopts a 56KWh lithium iron phosphate battery as the power source, and replaces traditional hydraulic components with electric cylinders, electric walking devices and slewing mechanisms to achieve all-electric drive. The overall efficiency of the machine is as high as over 70%, truly realizing zero exhaust emissions and low-noise operation.

Endurance: It can work continuously for no less than 8 hours on a full charge, which can basically meet the regular operation requirements for a whole day. The hourly usage cost is reduced by 65% compared with traditional excavators.

Operational performance

Wireless remote control operation: By eliminating the cab, operators can achieve precise control from a safe area far from the work site through wireless remote control devices or voice commands. This effectively avoids potential risks in traditional operation modes and enhances the safety and flexibility of operations.

Precise control: The combination of remote control operation and intelligent control system enables a control accuracy of up to 0.05mm. Operators can more precisely control the machine's running trajectory and working force, which can meet the engineering tasks with high requirements for excavation accuracy.

Intelligent control system.

Parameter collection and adjustment: Equipped with high-precision sensors and an intelligent control system, it can intelligently collect, analyze and adjust various operating parameters and machine postures in real time, ensuring that the excavator can maintain the best working state under all working conditions, significantly improving the operation accuracy and work efficiency.

Remote monitoring and diagnosis: By leveraging information technologies such as cloud computing and big data, remote monitoring and online fault diagnosis have been achieved, bringing great convenience to the maintenance and management of equipment and significantly reducing maintenance costs.

High-strength materials: High-strength steel and high-quality components are used in key parts to ensure the structural strength and stability of the excavator. It can withstand the working pressure under various complex working conditions and extend the service life of the equipment.

Applicable scenarios

Hazardous environment operation: It is suitable for flammable, explosive, toxic and harmful dangerous places, such as chemical industrial parks, mine blasting areas, etc. It can prevent operators from entering dangerous areas and ensure personnel safety.

Complex terrain operation: In complex terrains with poor road conditions and difficult access for personnel, such as mountainous areas, steep slopes, and marshes, operators can operate excavators in safe areas to carry out operations.

Urban construction and renovation: Due to its environmentally friendly and low-noise features, it is suitable for use in municipal engineering, building demolition, pipeline laying and other projects in the city center area, reducing the impact on the surrounding environment and residents.

| Key Spec | ||

| Product model | SH36E | |

| Total weight | kg | 3990 |

| Bucket capacity | m³ | 0.13 |

| Remote control performance | ||

| Remote control distance | km | 5 |

| Remote control delay | ms | 20 |

| Motor | ||

| Motor model | / | SLM180X3 |

| Motor power rating | kW/rpm | 8.5/65 |

| Battery performance | ||

| Battery system level | kWh | 56 |

| PACKvoltage | V | 1.5 |

| Total voltage | V | 8 |

| Main Performance | ||

| Travel speed (high/low] | km/h | 4.5/2.6 |

| Swing speed | r/min | 8.5 |

| Gradeability | 6 | 30 |

| Ground pressure | kPa | 39 |

| Bucket digging force | kN | 29 |

| Arm digging force | kN | 13 |

| Max.traction force | kN | 38 |

| Standard | ||

| Boom length | mm | 2540 |

| Arm length | mm | 1400 |

| Bucket capacity | m³ | 0.13 |

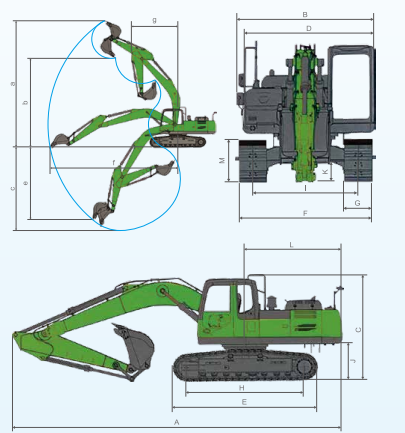

| Dimensions (mm) | ||

| A | Overall length | 5564 |

| B | Overall width | 1730 |

| C | Overall height | 2265 |

| D | Overallwidth ofuperstructure | 1600 |

| E | Track length | 2122 |

| F | Chassis width | 1730 |

| G | Track shoewidth | 300 |

| H | Track length on ground | 1640 |

| I | Track gauge | 1430 |

| J | Counterweigh clearance | 590 |

| K | Min.ground clearance | 295 |

| L | Min.tail swingradius | 1305 |

| M | Track height | 498 |

| Working Ranges(mm) | ||

| a | Max.digging height | 4930 |

| b | Max.dumping height | 3425 |

| C | Max.digingdepth | 3115 |

| e | Max.vertical walldigging depth | 2715 |

| f | Max.digging reach on ground | 5925 |

| g | Min.swing radius | 2890 |